Blockboard vs Chipboard

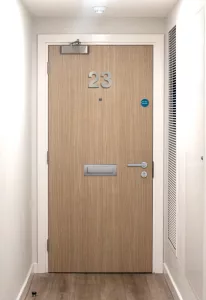

Chipboard, also known as particleboard is one of the most common door core for door leaves, as it is often perceived as the cheaper option. And, whilst there are sometimes cost savings to be hard with chipboard, very often more durable core types such as blockboard are comparable on price. Due to lack of specification support, customers are often left with a product that feels cheaper, without benefiting from the cost savings.

In this blog, we are going to compare the popular chipboard vs blockboard.

Both particleboard and blockboard can be used in door leaves and are available with a range of materials and components to achieve the desired specification. However, blockboard door cores have several major advantages over chipboard door cores.

Firstly, blockboard door leaves are around 6kg lighter per square metre than chipboard door leaves, which makes blockboard door cores easier to install and reduces installation time. Blockboard door cores are also perfect for passive fire protection and retrofit projects, where fast installation and rapid turn around times are paramount.

Although the blockboard door leaves are lighter, they are much more durable than chipboard door leaves. For example, when chipboard gets wet, it will expand and never return to its original shape whereas when blockboard gets wet, it will return back to its original shape due to it being made from natural pine.

In addition, blockboard is more stable and less likely to have warping along the length of the frame or cupping along the width of the frame. This means doorsets made with a blockboard door core are more stable.

Blockboard achieves this additional stability through its construction. Blockboard is formed using small staves of pine with the grains opposing, this adds greatly to the stability of the door core. Our ModuCore BB blockboard door has been designed to be the ultimate hard wearing door core.

Our ModuCore BB has also been designed with a laminate facing. This MDF facing was added for a wide range of finishing options, so architects and developers could meet the right specification for their project, whilst still benefiting from the lighter and more durable blockboard doorset.

We have high-specification doorsets manufactured at Selo House and in stock, which come with Certifire certification, including both fire rated and PAS 24 doorsets.

Modulo Doorsets were invented to simplify internal doorsets through solving problems with on-site adjustability, simple to specify and simple to install. Our doorsets come with a wide range of components and material to meet a wide range of specifications, so developers can have confidence that Modulo will help meet the cost and quality requirements for their projects.

We have a dedicated project support team on hand through our Halo Assist, which is designed to assist our customers from concept through to specification and completion. Our team will also be able to support with any after sales care. Our brand promise is we never walk away from a problem.

You can watch more about the difference between blockboard and chipboard here.